Specialized Manufacturer of

High-end Spherical Metal Powders

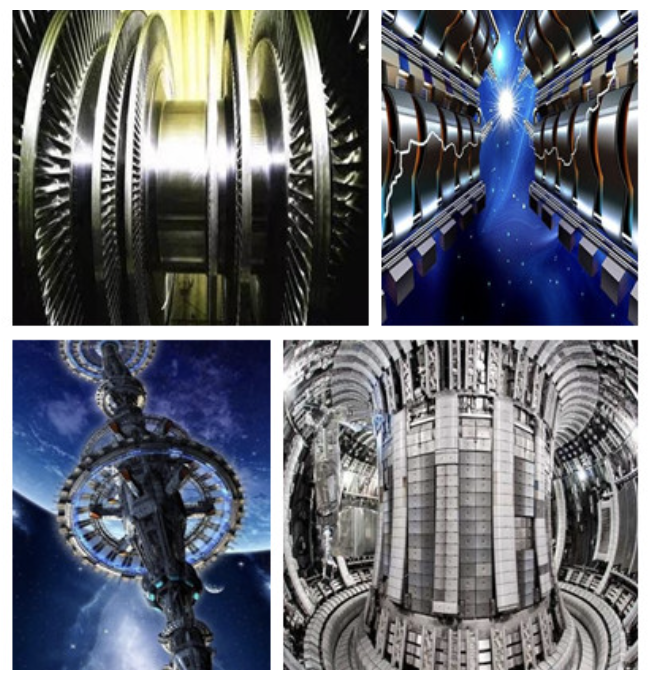

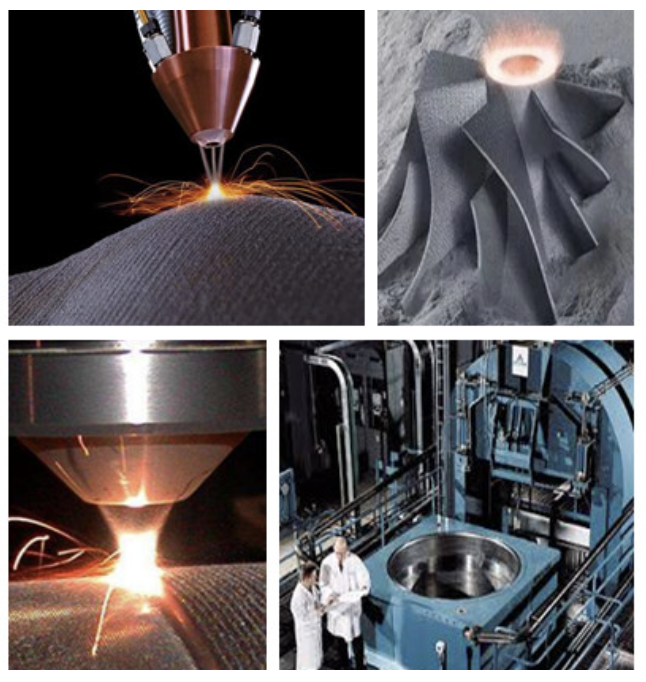

Shaanxi Inbo Metal Technology Co., Ltd. is located in the 3D Printing Base of Weinan National High-Tech Zone, specializing in the manufacturing of spherical metal powders for 3D printing. The company primarily utilizes the Plasma Rotating Electrode Process (PREP) to produce spherical metal powders. The main products include titanium and titanium-based alloys, nickel and nickel-based alloys, cobalt-based alloys, iron and iron-based alloys, copper and copper-based alloys, ultra-high-strength steel, intermetallic compounds, refractory metals such as tungsten, molybdenum, tantalum, niobium, hafnium, chromium, vanadium, zirconium, and their alloys. These powders are widely used in various fields such as aerospace, aviation, maritime, nuclear and atomic energy industries, biomedical applications, automotive, power equipment, rail transit equipment, and molds. The powders can be employed in processes such as 3D printing, hot isostatic pressing (HIP), sintering, repair spraying, and metal injection molding (MIM).

The company has a team of professionals with expertise in metallurgical powder technology, automatic control technology, and other fields. They possess advanced research and production techniques for spherical metal powders, and have accumulated rich experience and strong technical capabilities. The company has a complete production chain, including raw material processing, powder preparation, powder sieving and purification, as well as inspection and testing. They have independently developed powder production equipment and obtained multiple technological innovations and utility model patents. With the support of the advanced metal material composition analysis platform in Weinan’s national-level 3D printing base, the company has established inspection and testing instrument platforms for powder particle size, flowability, tap density, bulk density, morphology, and more. They have also established a sound quality management system, and obtained certifications for GJB9001C-2017 Weapon Equipment Quality Management System and ISO9001-2015 (GB/T19001-2016) International Quality Management System. The company’s product quality has been widely recognized by customers.

Adhering to the core values of “Technology Creates the Future, Quality Casts Brilliance,” the company actively promotes technological innovation, continuously develops more advanced production equipment and process technologies, and strives to provide customers with suitable products and high-quality services.